As an Amazon Associate, I earn from qualifying purchases.

Have you ever wondered how those small, fast printers spit out your receipts or labels so quickly? Understanding how thermal printers work can give you a new appreciation for the technology you use every day.

Whether you’re running a business, setting up your own shop, or just curious, knowing the secrets behind these printers can help you make smarter choices. Keep reading, and you’ll discover exactly what makes thermal printers tick—and why they might be the perfect fit for your needs.

Basics Of Thermal Printing

Thermal printing is a popular method for producing images and text on paper. It works by applying heat to special paper that changes color when heated. This process is fast, quiet, and requires fewer moving parts than other printers.

Understanding the basics of thermal printing helps explain why it is used in many industries. From receipts to labels, thermal printers offer a simple way to print without ink or toner.

Thermal Printing Technology

Thermal printing uses heat to create images on paper. A thermal print head heats specific spots on the paper. The paper has a coating that turns black or colored when heated. No ink or ribbons are needed in direct thermal printing.

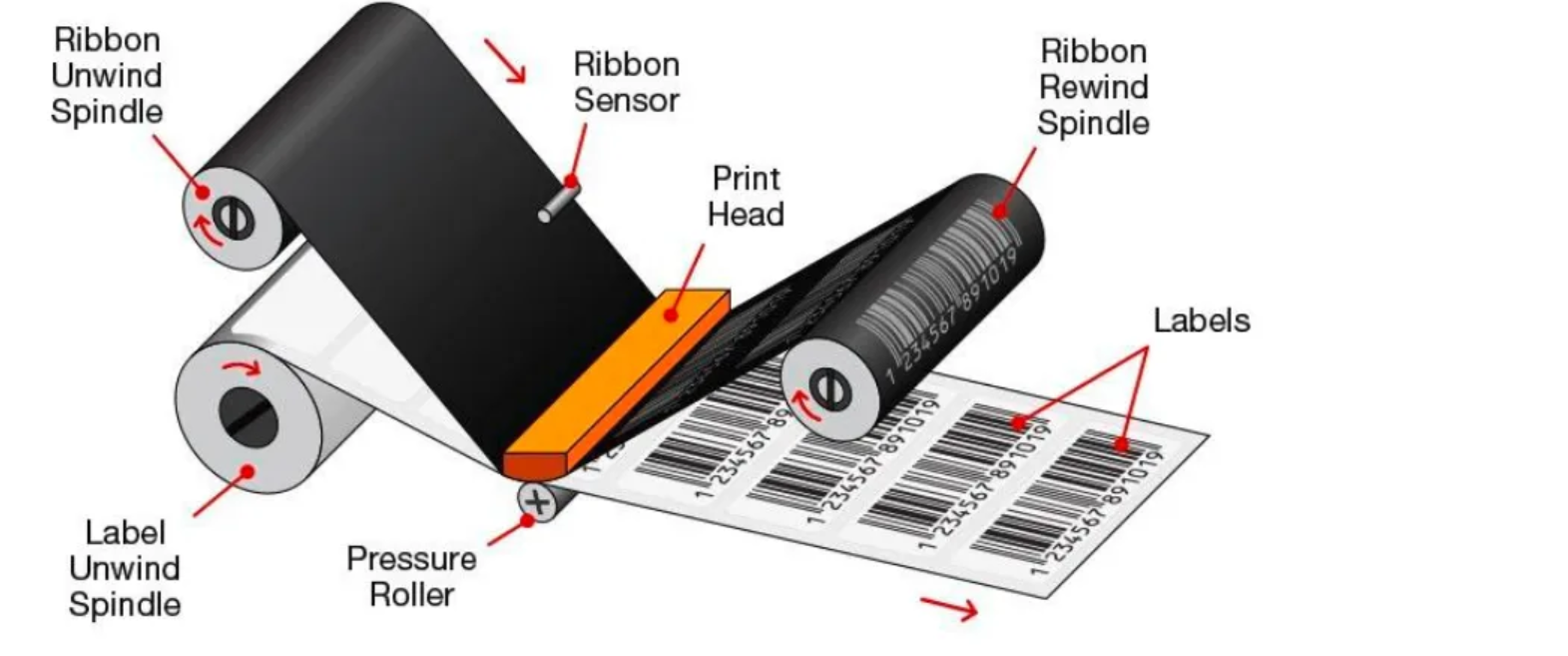

Some thermal printers use a ribbon with ink. The heat melts the ink from the ribbon onto the paper. This method is called thermal transfer printing. Both types produce clear, sharp prints quickly.

Types Of Thermal Printers

There are two main types of thermal printers. The first is direct thermal printers. They print by heating special heat-sensitive paper. The paper darkens where heated.

The second type is thermal transfer printers. They use a ribbon coated with ink. Heat transfers the ink from the ribbon to the paper. This type works on many materials, not just special paper.

Each type has its own uses. Direct thermal printers are common for receipts. Thermal transfer printers are popular for labels and barcodes.

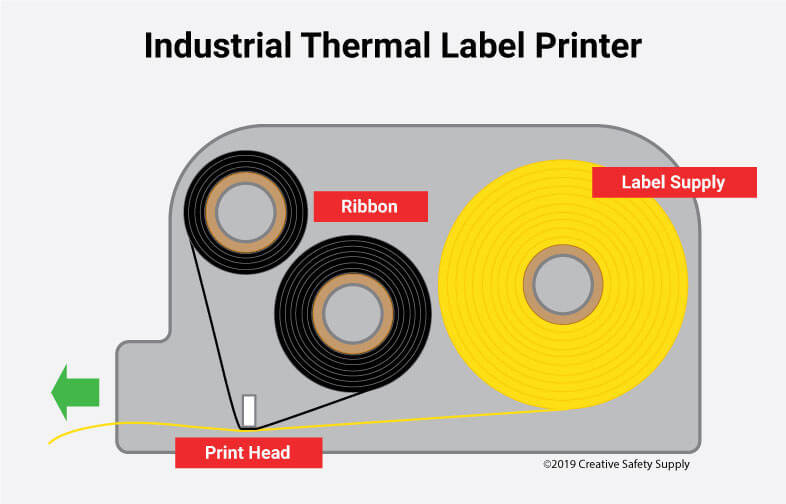

Key Components

Thermal printers have a few important parts. The thermal print head is the main part that heats up. It moves across the paper or stays still while the paper moves.

The platen roller helps feed the paper smoothly under the print head. The paper or ribbon roll holds the printing material. A controller manages the printing process.

These parts work together to produce fast and clear prints. Their design keeps printing simple and reliable.

Thermal Paper And Ink

Thermal printers need special materials to create clear prints. These materials include thermal paper and sometimes ink ribbons. Each plays a key role in producing sharp images and text. Understanding how these components work helps explain how thermal printers operate.

How Thermal Paper Works

Thermal paper has a special coating that reacts to heat. When the printer’s thermal head heats parts of the paper, the coating changes color. This change creates the printed image or text without using ink.

The paper is sensitive to temperature and pressure. The printer controls heat in tiny spots to form letters and pictures. This method is fast and quiet, making thermal printing popular.

Role Of Thermal Ink Ribbons

Some thermal printers use ink ribbons to add color or improve print quality. These ribbons have ink that melts when heated by the printer’s thermal head. The melted ink sticks to regular paper or special thermal transfer paper.

Ink ribbons help print images that last longer and resist fading. They allow printing on different types of paper, not just thermal paper. This expands the printer’s use beyond receipts to labels and tags.

Printing Process Explained

The printing process in thermal printers is simple and fast. It uses heat to create images on special paper. This method does not need ink or toner. The process is quiet and clean, making it ideal for many uses. Understanding how this works helps appreciate the technology behind receipts and labels.

Two main steps make up the printing process. First, heat is applied to the paper in a controlled way. Then, the image forms clearly on the paper surface. Each step plays a key role in producing sharp and readable prints.

Heat Application Mechanism

Thermal printers have a print head with tiny heating elements. These elements heat up quickly in specific patterns. The heat touches the special thermal paper only where the image needs to appear. The paper is coated with heat-sensitive chemicals. These chemicals react to the heat by changing color. This selective heating creates the dots or lines that build the image.

Image Formation On Paper

As the print head moves across the paper, it activates the heating elements. The paper moves steadily under the print head. The heat spots form black or colored marks on the paper. These marks combine to form text or graphics. The image appears instantly and dries fast. This process ensures clear, sharp prints every time.

Credit: www.creativesafetysupply.com

Advantages Of Thermal Printers

Thermal printers offer several key benefits that suit many businesses and personal uses. They work by heating special paper, which creates images or text. This method brings distinct advantages over other printing types.

Speed And Efficiency

Thermal printers print very fast. They do not need time to dry ink or align cartridges. This quick process helps complete tasks faster. Many shops and offices prefer these printers for fast receipts and labels.

Low Maintenance

Thermal printers require little care. They have fewer moving parts than inkjet or laser printers. This means less chance of breakdowns. Also, they do not need ink or toner refills. This saves money and reduces hassle.

Print Quality And Durability

Prints from thermal printers are clear and sharp. The text and images last long without fading. This is important for receipts, barcodes, and labels. The prints stay readable even after handling or exposure to light.

Common Uses Of Thermal Printers

Thermal printers are popular in many fields due to their speed and reliability. They use heat to create images on special paper. This makes them ideal for tasks that need quick, clear printing without ink. Here are some common uses of thermal printers across different industries.

Retail And Point Of Sale

Thermal printers are widely used at checkout counters. They print receipts quickly for customers. The printers help reduce waiting time during busy hours. Store staff find thermal printers easy to use and maintain. They produce clear, smudge-free receipts that last long.

Shipping And Logistics

Thermal printers play a key role in shipping. They print shipping labels that stick firmly to packages. These labels include barcodes and delivery information. The fast printing helps speed up the packing and shipping process. Thermal printers work well in warehouses and shipping centers.

Healthcare Applications

Hospitals and clinics use thermal printers for patient care. They print wristbands with patient details for identification. Thermal printers also print labels for lab samples and medicines. The clear, durable prints help avoid errors. They support smooth operation in busy healthcare settings.

Challenges And Limitations

Thermal printers offer many benefits but also come with challenges and limits. Understanding these helps users choose the right printer for their needs. Some issues affect print quality and device lifespan. Others impact cost and convenience.

Sensitivity To Heat And Light

Thermal paper reacts to heat to create images. This makes the prints sensitive to external heat sources. Leaving receipts in hot places can cause fading or darkening. Strong sunlight also harms the printed text and images.

Over time, exposure to heat and light can make prints unreadable. This limits how long thermal prints last. Businesses needing long-term records might face problems. Protecting prints with covers or storing them properly helps reduce damage.

Paper Costs And Availability

Thermal printers require special thermal paper. This paper costs more than regular paper. The price can add up for heavy users. Some regions have limited availability of thermal paper brands. This may cause delays or higher expenses.

Using the right paper type is important. Lower quality paper can cause jams and poor print quality. Finding reliable suppliers ensures smooth printer operation. Planning paper purchases helps avoid running out at critical times.

Future Trends In Thermal Printing

The future of thermal printing holds exciting changes. New technology aims to improve speed, quality, and durability. These improvements will make thermal printers more useful in many fields. From retail to healthcare, the impact will be significant. Below are key trends shaping the future of thermal printing.

Advancements In Materials

Thermal paper and ribbons are evolving. New materials resist fading and smudging better. This means printed labels and receipts last longer. Some materials will be eco-friendly, reducing waste. This helps businesses meet green standards. These improvements also cut costs over time.

Integration With Digital Technologies

Thermal printers will connect more with digital tools. Cloud printing lets users print from anywhere. Mobile apps will control printers easily. Data from printers will help track inventory and sales. This integration makes businesses faster and more efficient.

Credit: www.bentsaishop.com

Credit: www.peaktech.com

Frequently Asked Questions

How Do Thermal Printers Create Images On Paper?

Thermal printers use heat to activate special paper coated with heat-sensitive chemicals. The heated print head selectively heats areas, turning them dark to form images or text. This process eliminates the need for ink or toner, making printing fast and quiet.

What Types Of Paper Do Thermal Printers Use?

Thermal printers use specially coated thermal paper designed to react to heat. This paper is smooth and contains heat-sensitive dye layers that change color when heated. Using the correct paper ensures clear, long-lasting prints and prevents damage to the printer.

Are Thermal Printers More Cost-effective Than Inkjet Printers?

Yes, thermal printers often cost less to maintain since they don’t use ink or toner cartridges. They require only thermal paper, which is generally affordable. However, initial printer costs and paper quality can affect overall expenses.

What Industries Commonly Use Thermal Printers?

Thermal printers are popular in retail for receipts, logistics for shipping labels, and healthcare for wristbands. Their speed, reliability, and low maintenance make them ideal for environments requiring quick, clear prints.

Conclusion

Thermal printers create images by heating special paper. They work fast and need no ink. This makes them useful for many businesses. You find them in stores, hospitals, and offices. Knowing how they work helps you choose the right printer.

They save time and reduce costs. Simple technology with practical uses. Understanding this helps you see their value. Thermal printers stay popular for many reasons. Easy, quick, and reliable printing every time.

As an Amazon Associate, I earn from qualifying purchases.