As an Amazon Associate, I earn from qualifying purchases.

Are you struggling to keep track of your Industrial Control System (ICS) components? Knowing which ICS functional area monitors can save you time and prevent costly mistakes.

These monitors act like your system’s watchdogs, keeping everything running smoothly and alerting you when something goes wrong. You’ll discover exactly which monitors you need and how they protect your operations. Keep reading to gain the confidence and control your ICS setup deserves.

Ics Functional Areas

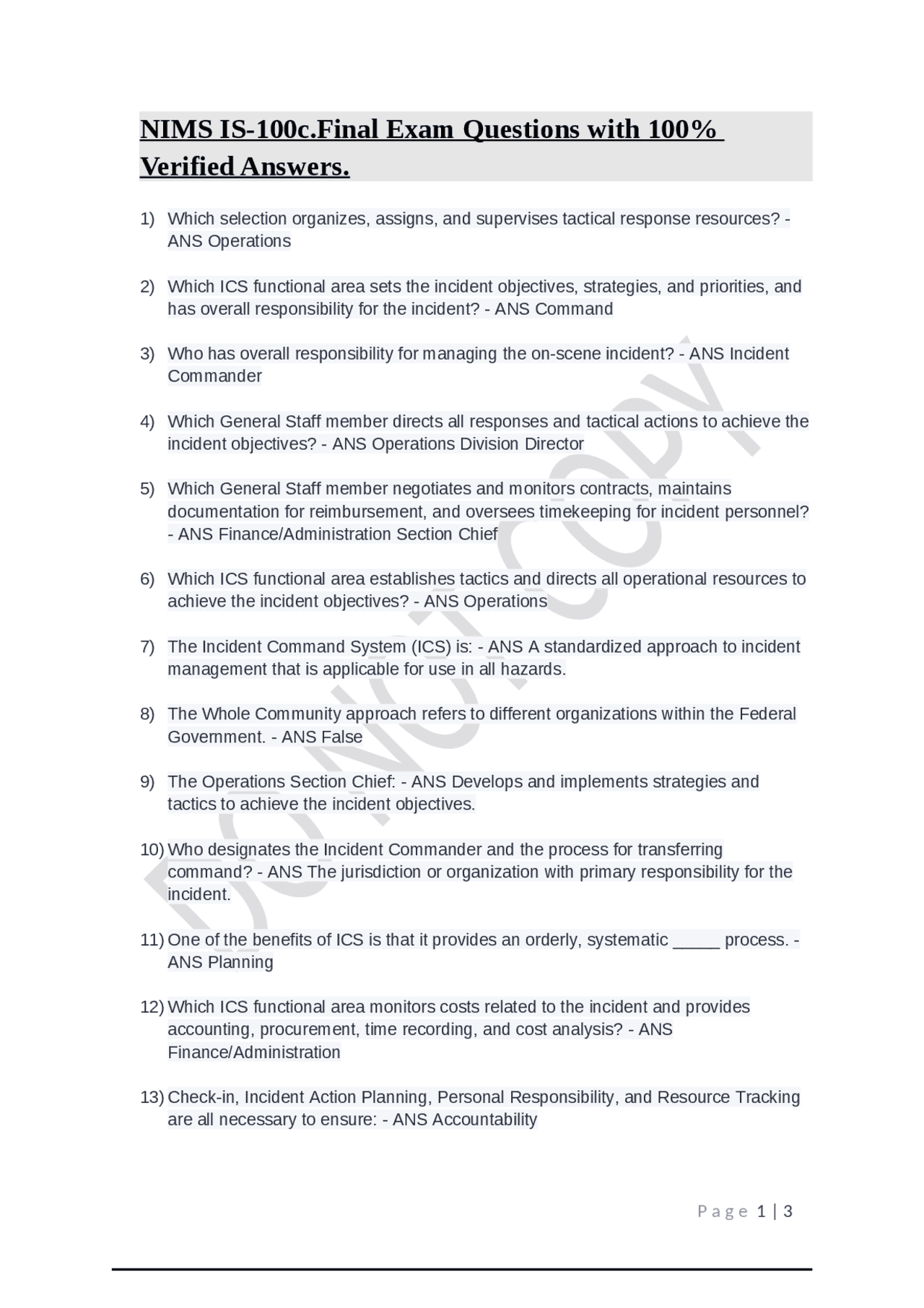

The Incident Command System (ICS) is a structured way to manage emergencies. It divides the response into different functional areas. Each area has a specific job to keep things organized. These areas work together to handle incidents effectively. Understanding ICS functional areas helps in knowing who does what during a crisis.

Key Components

ICS functional areas include Command, Operations, Planning, Logistics, and Finance. The Command sets the overall goals and direction. Operations carry out the tasks needed to control the incident. Planning gathers information and makes action plans. Logistics provides support, supplies, and services. Finance manages costs and tracks expenses.

Roles And Responsibilities

Each functional area has clear roles and duties. The Incident Commander leads and makes decisions. Operations Chiefs manage teams that do the work. Planning Chiefs collect data and prepare reports. Logistics Chiefs ensure resources reach the right places. Finance Chiefs handle budgeting and record keeping. This clear structure helps avoid confusion during emergencies.

Monitoring In Ics

Monitoring in Industrial Control Systems (ICS) plays a key role in keeping processes safe and efficient. It involves watching various parts of the system to catch problems early. This helps prevent damage, downtime, and security risks.

Operators and engineers rely on monitoring to track system health and performance. Data collected during monitoring guides quick decisions and fixes. Without proper monitoring, small issues can grow into major failures.

Purpose And Importance

Monitoring ensures ICS runs smoothly and safely. It helps detect faults and unusual activities early. This reduces the chance of accidents and costly repairs.

Effective monitoring supports compliance with safety standards. It also improves system reliability and efficiency. Teams can respond faster to emergencies and reduce downtime.

Common Monitoring Tools

SCADA systems are popular tools for ICS monitoring. They provide real-time data and control of processes. Sensors collect information about temperature, pressure, and flow.

Network monitoring tools check communication between devices. They help find cyber threats and network failures. Alarm systems alert staff to critical issues immediately.

Functional Areas That Monitor

The Incident Command System (ICS) organizes response efforts by dividing tasks into clear functional areas. Each area monitors specific activities to keep the operation running smoothly. Understanding these areas helps everyone know their role during an incident.

These functional areas work together. They track progress, manage resources, and solve problems quickly. Their focused monitoring improves safety and efficiency.

Operations Section

The Operations Section handles the main tasks during an incident. It monitors the actions taken to control or fix the situation. This section directs personnel and equipment where needed most.

They watch over the response activities closely. Their goal is to meet the incident objectives safely and fast. They adjust plans as conditions change on the ground.

Planning Section

The Planning Section collects and evaluates information about the incident. It monitors the overall situation and predicts future needs. This section keeps detailed records and updates the incident action plan.

They track resources and identify potential problems. Their work supports decision-making and helps keep the response organized. Planning ensures the team stays prepared for what comes next.

Logistics Section

The Logistics Section provides support to all teams in the field. It monitors supply lines, equipment, and facilities. This section ensures responders have what they need to work effectively.

They track transportation, communication, and food services. Their role is essential for smooth operations and responder well-being. Logistics keeps the response moving without delays.

Finance/administration Section

The Finance/Administration Section monitors costs and administrative tasks. It tracks expenses, contracts, and personnel time. This section ensures all financial records are accurate and complete.

They manage claims and documentation for reimbursement. Their monitoring helps control budgets and supports legal requirements. Finance keeps the response accountable and transparent.

Operations Section Monitoring

The Operations Section Monitoring plays a vital role in managing incident response. It focuses on tracking and supervising various activities on the ground. This ensures that all tasks are done efficiently and safely. The section helps keep the entire operation on course and supports decision-making.

Operations Section Monitoring involves constant observation and communication. It gathers real-time information about the incident. This allows quick adjustments and resource allocation. The section acts as the eyes and ears during an emergency response.

Field Activity Tracking

Field Activity Tracking involves watching the actions of teams working on site. It records what tasks are being done and where. This helps avoid confusion and overlaps. Tracking also shows if any team needs help or extra tools. It keeps the operation organized and smooth.

Resource Status

Resource Status means knowing which equipment and personnel are available. It tracks the condition and location of resources. This information helps managers send the right tools to the right place. It prevents shortages and delays in the response effort. Keeping updated resource status is crucial for success.

Incident Progress

Incident Progress monitoring shows how far the response has come. It measures completed tasks against the plan. This helps leaders understand if the incident is under control. Monitoring progress also identifies any problems early. It supports quick decisions to keep the operation moving forward.

Planning Section Monitoring

The Planning Section plays a key role in managing incidents. It watches and checks many important details. This section helps the team stay ready and organized. Monitoring this area ensures smooth operations during emergencies.

Situation Analysis

Situation analysis means reviewing the current event. The Planning Section gathers facts from different sources. They check what is happening and what might change. This helps the team understand the situation fully. Clear information guides better decision-making and response plans.

Resource Forecasting

Resource forecasting predicts what supplies and tools are needed. The Planning Section tracks available resources carefully. They estimate what will be used soon and what might run out. This planning avoids shortages and keeps the response strong. Proper forecasting saves time and effort.

Documentation Management

Documentation management keeps all records in order. The Planning Section files reports, maps, and plans systematically. Accurate records help track progress and changes. Well-kept documents support clear communication among teams. This process ensures nothing important is missed or lost.

Credit: www.gauthmath.com

Logistics Section Monitoring

The Logistics Section is a key part of the Incident Command System (ICS). It handles all support needs during an emergency or event. Monitoring this section ensures resources move smoothly. It helps keep operations efficient and safe.

This section covers many tasks. From tracking supplies to managing equipment. Each task needs careful attention. The right information at the right time can save efforts and lives.

Supply Chain Tracking

Supply chain tracking keeps an eye on all incoming and outgoing materials. It shows where supplies are and when they arrive. This helps avoid shortages or delays. Clear records prevent confusion and wasted time.

Monitoring supply chains also helps plan for future needs. It ensures the right items reach the right place quickly. This saves resources and supports the whole operation.

Support Services

Support services provide essential help to the team. This includes food, water, shelter, and transportation. Monitoring these services ensures everyone gets what they need. It keeps the team strong and ready.

Good support also boosts morale. It shows that the team is cared for. This can improve focus and efficiency during tough situations.

Equipment Status

Equipment status monitoring tracks tools and machines used in the operation. It records which equipment is available or needs repair. This prevents breakdowns and delays in the field.

Knowing the condition of equipment helps plan work better. It ensures the team always has what they need to do their job safely and well.

Finance/administration Monitoring

The Finance/Administration Monitoring function in the ICS structure plays a crucial role. It keeps financial and administrative activities on track. This area ensures that resources are used wisely and transparently. It helps the incident run smoothly by managing costs, time, and purchases.

Cost Tracking

Cost tracking is the process of recording all expenses during an incident. It helps to know where money is spent. This information is vital for budgeting and reporting. Keeping costs organized prevents overspending and errors. It supports clear financial decisions throughout the incident.

Timekeeping

Timekeeping monitors the hours worked by staff and resources. Accurate records ensure fair pay and resource management. It helps avoid confusion about work hours and shifts. Timekeeping data also aids in evaluating the incident’s labor costs. This process contributes to smooth administrative operations.

Procurement Oversight

Procurement oversight controls the buying of goods and services. It ensures purchases follow rules and budgets. This function prevents waste and fraud in spending. Monitoring procurement keeps the supply chain efficient and reliable. It supports the timely delivery of needed items to the incident.

Credit: www.docsity.com

Integrating Monitoring Across Areas

Integrating monitoring across different ICS functional areas is essential for smooth operations. It helps teams work together and respond quickly to issues. Combining information from multiple areas gives a clearer picture of the system’s health. This approach reduces risks and improves overall efficiency.

Communication Channels

Clear communication channels connect all ICS functional areas. Teams share updates and alerts through secure platforms. This reduces delays and avoids confusion. Consistent communication ensures everyone stays informed and can act fast.

Data Sharing

Data sharing links monitoring tools across different areas. It allows real-time access to important information. Teams can spot trends and detect problems early. Sharing data helps prevent failures and supports better planning.

Decision Making

Integrated monitoring supports faster, smarter decision making. Teams use combined data to assess situations accurately. This leads to informed choices that protect system stability. Collaboration improves response times and reduces costly mistakes.

Challenges In Ics Monitoring

Monitoring Industrial Control Systems (ICS) comes with many challenges. These challenges affect how well the system works and how safe it remains. Understanding the main problems helps in creating better solutions. Let’s explore the key difficulties faced in ICS monitoring.

Information Overload

ICS generate large amounts of data every second. This data can be hard to manage and analyze. Operators may miss important alerts due to too much information. Sorting through this data takes time and skill. This overload slows down decision-making and response times.

Coordination Issues

Many teams handle different parts of ICS. Communication gaps can cause delays or errors. Lack of clear roles leads to confusion during incidents. Coordinating between IT and OT teams is often difficult. This slows down problem-solving and recovery efforts.

Technological Limitations

Some ICS use outdated equipment and software. These older systems may not support modern monitoring tools. Security patches and updates can be missing. Limited technology makes detecting threats harder. It also reduces the ability to respond quickly to problems.

Credit: www.gauthmath.com

Best Practices For Effective Monitoring

Effective monitoring is essential for managing ICS functional areas smoothly. It helps teams respond quickly to issues and maintain control. Best practices ensure that monitoring is clear, timely, and useful for everyone involved.

Following these practices improves communication and reduces errors. Teams stay alert and informed. They can track progress and solve problems faster.

Clear Roles

Assign specific monitoring duties to each team member. Everyone must know their tasks and responsibilities. Clear roles prevent confusion and overlap. This clarity helps teams focus on their areas. It also speeds up decision-making.

Real-time Updates

Use tools that provide instant information. Real-time updates keep everyone aware of changes. Quick data sharing allows fast reactions. It reduces delays and misunderstandings. Teams can adjust strategies based on current facts.

Training And Drills

Regular training improves monitoring skills. Practice drills prepare teams for real situations. Training builds confidence and teamwork. Drills reveal weaknesses and areas to improve. Continuous learning keeps monitoring effective and reliable.

Frequently Asked Questions

What Does Ics Functional Area Monitors Do?

ICS Functional Area Monitors track and display specific control system data. They help operators monitor key processes efficiently. These monitors improve situational awareness and enable quick decision-making in industrial control systems.

Which Ics Areas Are Commonly Monitored?

Commonly monitored ICS areas include power generation, water treatment, manufacturing, and HVAC systems. Each area has unique parameters that require constant observation to ensure safety and optimal performance.

How Do Ics Functional Area Monitors Improve Safety?

They detect anomalies and alert operators to potential hazards early. This proactive approach reduces downtime and prevents accidents, enhancing overall plant safety and compliance with regulations.

Can Ics Functional Area Monitors Integrate With Scada?

Yes, these monitors often integrate seamlessly with SCADA systems. Integration allows centralized control and real-time data visualization, improving operational efficiency and system management.

Conclusion

ICS functional area monitors play a key role in system safety. They keep an eye on specific parts of industrial control systems. This monitoring helps spot problems early and avoid downtime. Choosing the right monitor depends on the system’s needs and risks.

Regular checks ensure smooth operation and protect equipment. Understanding these monitors helps you keep systems reliable and secure. Stay informed to maintain control system health and safety effectively.

As an Amazon Associate, I earn from qualifying purchases.